Introduction

A phosphorus triiodide manufacturing plant project report provides a detailed roadmap for establishing a facility to produce phosphorus triiodide, a chemical compound widely used in organic synthesis and chemical reactions. This report includes insights into production processes, machinery requirements, safety protocols, and market trends, serving as a vital tool for entrepreneurs and investors venturing into the chemical manufacturing sector.

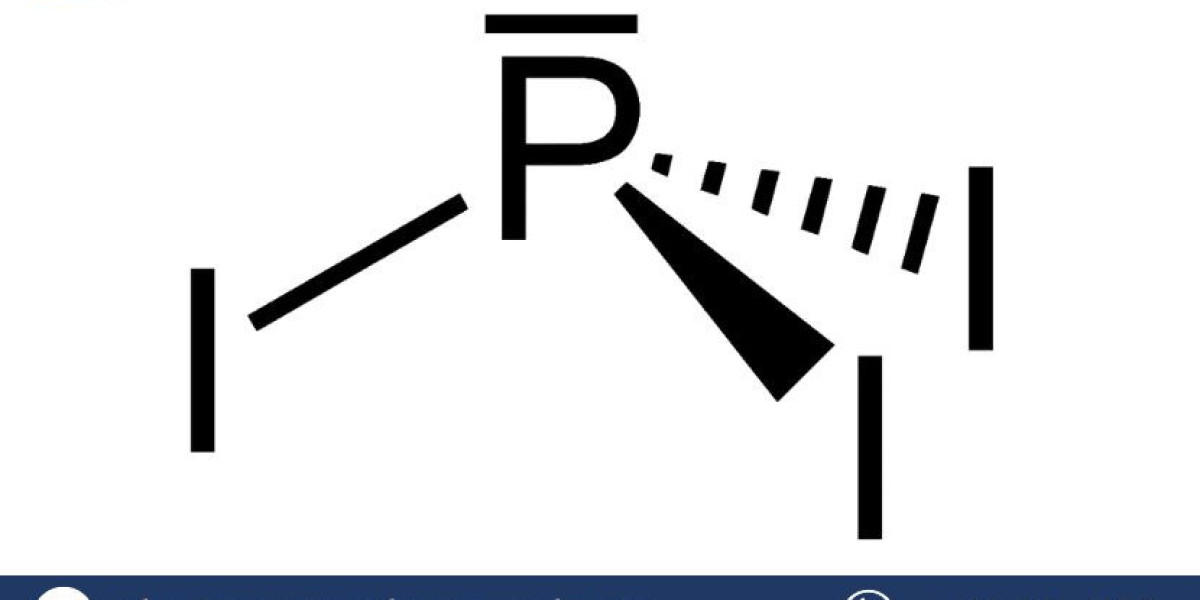

Overview of Phosphorus Triiodide

Phosphorus triiodide (PI₃) is a red crystalline solid with applications in the pharmaceutical, agrochemical, and research industries. It is primarily used as a reagent to convert alcohols into alkyl iodides and is valued for its efficacy in organic synthesis. Its production requires stringent control measures due to the reactive nature of its components.

Market Demand and Applications

The demand for phosphorus triiodide is influenced by its versatile applications:

- Pharmaceutical Industry: Used in synthesising intermediates for active pharmaceutical ingredients (APIs).

- Agrochemical Sector: Employed in the formulation of certain pesticides and herbicides.

- Laboratory Use: Frequently utilised in academic and industrial research for chemical transformations.

The rising need for specialty chemicals in various industries continues to drive the demand for phosphorus triiodide.

Steps to Establish a Phosphorus Triiodide Manufacturing Plant

Setting up a manufacturing plant for phosphorus triiodide involves several critical steps:

- Feasibility Study: Assess the market potential, demand-supply dynamics, and competition.

- Location Selection: Choose a site with access to raw materials, utilities, and transportation networks.

- Technology and Machinery: Procure advanced equipment for synthesis, purification, and packaging.

- Safety Measures: Implement robust safety protocols due to the reactive and hazardous nature of phosphorus triiodide.

- Regulatory Compliance: Ensure adherence to environmental and industrial safety standards.

Get a Free Sample Report with Table of Contents@

Production Process of Phosphorus Triiodide

The production of phosphorus triiodide involves the direct reaction of phosphorus with iodine under controlled conditions. The steps include:

- Raw Material Preparation: Phosphorus and iodine are weighed and prepared in the required stoichiometric ratio.

- Reaction: The materials are combined in a reaction vessel, where iodine reacts with phosphorus to form phosphorus triiodide.

- Purification: The crude product is purified to remove impurities and ensure high purity levels.

- Packaging: The final product is packaged in airtight containers to prevent moisture absorption and degradation.

Each stage requires precision and expertise to ensure product quality and safety.

Key Components of a Project Report

A comprehensive phosphorus triiodide manufacturing plant project report should include:

- Market Analysis: Overview of industry trends, growth drivers, and demand patterns.

- Technical Details: Description of the production process, equipment requirements, and plant layout.

- Safety Protocols: Guidelines for handling hazardous materials and emergency response measures.

- Financial Projections: Detailed cost analysis, revenue forecasts, and investment requirements.

- Risk Assessment: Identification of potential risks and strategies for mitigation.

Benefits of Manufacturing Phosphorus Triiodide

- High Market Demand: Its use in diverse industries ensures steady demand.

- Specialised Product: Limited competition due to the technical expertise required for production.

- Export Opportunities: Significant demand in international markets for high-quality chemical reagents.

Challenges

The manufacturing process of phosphorus triiodide comes with specific challenges:

- Hazardous Materials: Both phosphorus and iodine are reactive and require careful handling.

- Environmental Concerns: Compliance with environmental regulations to manage waste and emissions.

- High Capital Investment: Advanced machinery and safety systems demand substantial initial investment.

- Skilled Workforce: Trained personnel are essential to manage production and ensure safety.

Sustainability in Chemical Manufacturing

Sustainable practices in phosphorus triiodide manufacturing can minimise environmental impact and improve operational efficiency. These include:

- Waste Management: Proper disposal and recycling of by-products.

- Energy Efficiency: Use of energy-efficient equipment and processes.

- Green Chemistry: Exploring environmentally friendly methods to reduce the use of hazardous substances.

FAQs

Q1: What is phosphorus triiodide primarily used for?

It is commonly used in organic synthesis, especially for converting alcohols into alkyl iodides.

Q2: What safety measures are essential for phosphorus triiodide production?

Robust safety protocols, including proper storage of raw materials, use of personal protective equipment, and emergency response plans, are critical.

Q3: What certifications are required for a phosphorus triiodide manufacturing plant?

Compliance with environmental, health, and safety regulations, along with certifications such as ISO 9001 and ISO 14001, may be necessary.

Q4: Can phosphorus triiodide be exported?

Yes, it is in demand globally, particularly in the pharmaceutical and agrochemical industries.

Q5: How can sustainability be achieved in phosphorus triiodide production?

By adopting energy-efficient technologies, reducing waste, and exploring green chemistry practices.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au